Wastewater Treatment

Anaerobic Digesters

Anaerobic Treatments

Fat, Oil, and Grease (FOG) substrates are like rocket fuel for your digester. But when you get too much FOG compounds, they can often lead to foaming. The biocatalysts in Ana-Zyme G® allow you to keep the gas production high and the operations running. Anaerobic digestion requires a stable pH and balanced micronutrients. ANAGEN-Biogas® and SELECT-pH® provide both.

ANAGEN-Degrease®

ANAGEN-Degrease®

Biocatalyst for anaerobic breakdown of FOG

ANAGEN-Degrease® – Biocatalyst for anaerobic breakdown of FOG

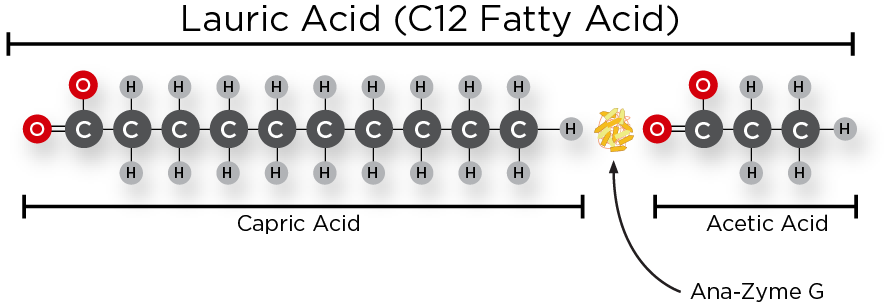

ANAGEN-Degrease® is formulated to provide immediate reduction of fat, oil, and grease in anaerobic digesters and lagoons to avoid issues with grease caps and foaming. The biocatalysts in ANAGEN-Degrease® rapidly speed the breakdown of complex fat molecules into simple short-chain fatty acids which then break down to acetic acid – a compound used in methanogenesis.

The goal of this product is to limit volatile acid accumulation, while also increasing biogas generation, and improving volatile solids destruction.

ANAGEN-Degrease® can degrade a range of fatty acids such as linolenic, oleic, stearic, and palmitic as well as fish oils, triglycerides, dairy, and egg fat. The production of short-chain fatty acids is very important as part of the acidogenesis–methanogenesis process.

The Science Behind It

High Levels of Grease In Anaerobic Digesters

FOG must undergo several steps to be converted into acetate, the ideal food substrate for methanogens: disintegration, hydrolysis, and β-oxidation.

Limitations in the rates of any of these steps can lead to uneven degradation of FOG, which results in variable volatile acid loading on methanogens. Variable loading of volatile acids can easily overwhelm methanogens leading to accumulation of volatile acids, eventually resulting in a drop in digester pH. These impacts are exacerbated in systems with high FOG loading.

However, FOG can be made into an excellent food substrate for anaerobic digestion, due to their high COD content, as well as their high potential to generate large quantities of acetate or acetic acid. It just needs a little processing to get there.

ANAGEN-Degrease® and Anaerobic Grease

ANAGEN-Degrease® acts as a catalyst to naturally occurring bacteria to aid in the breakdown of FOG, which prevents the overloading of methanogens and frees up this new food source. ANAGEN-Degrease® does this by targeting triglycerides and long-chain fatty acids to convert them evenly into short-chain fatty acids. This stabilization of fatty acid degradation allows methanogens to better acclimate to fatty acid loading. They are then able quickly uptake these fatty acids, reducing the chances of volatile fatty acid accumulation. In addition, ANAGEN-Degrease® prevents the accumulation of undegraded fats in a system, which enhances volatile solids destruction, particularly in systems with limited mixing such as lagoons.

Applications

Anaerobic digesters/lagoons for:

- Dairy processing

- Meat processing

- High-fat food processing

Benefits

- Eliminates grease caps

- Avoid foaming due to fats, oils and greases

- Prevents the buildup of fatty acids

- Improves VA: ALK Ratio

Downloads

ANAGEN-Protein®

ANAGEN-Protein®

Biocatalyst That Speeds Digestion of Proteins in Anaerobic Digesters

ANAGEN-Protein® is a biocatalyst specifically formulated to quickly and thoroughly degrade complex proteins commonly found in the anaerobic waste of meatpacking, rendering, food processing, or farming facilities.

Proteinaceous materials are among the most difficult substrates for anaerobic digesters to break down, due to their high nitrogen concentration. They often hinder anaerobic digester performance by passing through the process before they can be completely degraded. ANAGEN-Protein® bridges the gap between the considerable potential of anaerobic digesters and difficult proteins by breaking them down in a way that methanogens cannot. The rapid hydrolysis of these complex proteins into soluble amino acids creates food and an environment more favourable for methanogenic bacteria.

Applications and Benefits

Applications

Anaerobic digesters/lagoons for:

– Dairy processing

– Meat processing

Benefits

– Improves anaerobic enzyme production

– Improves volatile solids destruction

– Improves methane production

– Releases amino acids from complex proteins

The Difficulty of Degrading Proteins Anaerobically

Anaerobic bacteria tend to be poorly specialized for the degradation of protein. Carbohydrates usually make better feed substrates than protein due to their high cBOD content and the low nitrogen requirements of anaerobic bacteria. Fat, oil, and grease—while usually undesirable in a digester—also have a high cBOD content. This means that anaerobic hydrolysis favours the degradation of fats and complex sugars, over the degradation of proteins. However, when broken down, protein provides valuable amino acids which improve the production of naturally occurring anaerobic enzymes. When free amino acids are absent, anaerobic bacteria need to produce them using simple carbon substrates and ammonia, a process that takes additional metabolic steps and wastes carbon, making the process inefficient.

ANAGEN-Protein® improves anaerobic efficiency by outsourcing that extra metabolic step in the degradation of proteins so the anaerobic bacteria can focus their resources on breaking down carbon substrates and producing methane. This leads to improved methane generation, lowers effluent COD, and improved volatile solids destruction.

Downloads

ANAGEN-Booster®

ANAGEN-Booster®

Boost Digester Performance

ANAGEN-Booster® provides the building blocks to anaerobic life. This product provides methane-forming bacteria with a COD and micronutrient source specific for their growth and stabilization, allowing them to increase their methane production. Use ANAGEN-Booster® in the following situations:

#1. When methane formers cannot keep up with variable high loadings or persistent low loadings.

#2. When operators are having trouble building methanogen populations.

#3. During new digester start up.

#4. To improve methane production.

#5. To stabilize digester pH by improving digester microbiota.

This product shines in plants with variable loading or consistently low loading.

The Science Behind It

When methanogens become stressed they lose the ability to produce methane, which leads to a buildup of volatile acids. That build-up reduces the pH which causes the digester to be acidic (sour) and leads to poor digester performance. Generally, a digester is considered sour if the pH in the digester is too low to allow for significant amounts of methane production. Generally, this occurs below pH 6. If a digester is already sour, the pH should be adjusted before any other treatment is attempted. Sour digesters have a buildup of methanogen substrate which means the food supplement may actually make the problem worse. After a neutral pH has been reestablished, the food supplement can be used to improve pH stability.

Anaerobic digesters contain a variety of facultative bacteria, strictly anaerobic bacteria, and archaea (such as methanogens) which allow a digester to break down volatile solids. Volatile solids are converted to soluble compounds by hydrolysis and then to short-chain fatty acids by the acid-generating bacteria. Once short-chain volatile acids are present in an anaerobic system, the methane generators use the acids to produce biogas (primarily methane and carbon dioxide). The archaea responsible for methane production are much more susceptible to adverse conditions than acid-generating bacteria (acetogens) and this is why anaerobic food supplement is so helpful. Anaerobic food supplement supplies methanogens with the COD and micronutrients they need so their populations can build during periods of low nutrient loading.

Companion Products

ANAGEN-Biogas® supplies methanogen-producing bacteria with the most important trace elements to help them convert food sources into gas, creating a more stable and productive anaerobic digester.

ANAGEN-Degrease® handles the volatile fat, oil, and grease that enter anaerobic digesters and can cause foaming and upsets. Anaerobic digesters that use ANAGEN-Degrease® are less likely to go sour than digesters that don’t.

Downloads

ANAGEN-Biogas®

ANAGEN-Biogas®

Anaerobic Micronutrients

ANAGEN-Biogas® contains a blend of 10 bioavailable micronutrients that are specifically designed to improve anaerobic digestor performance and improve methane production. The spectrum of micronutrients in ANAGEN-Biogas® provides the soluble trace elements needed to optimize gas production.

The balance of its soluble trace elements is the result of almost a decade of research and field applications and can offer a superior bioavailability. The result is improved volatile solids conversion, a healthier population of methanogenic archaea, and a better quality of biogas production. This product is backed by complete technical and laboratory services for all customers.

For an in-depth analysis on your digestor’s trace elements, talk to your technical rep for information on our soluble micronutrient analysis.

Safe and effective results in:

Complete mix anaerobic digestors

Covered lagoons

CSTRs

UASBs

Applications and Benefits

ANAGEN-Biogas® Applications

– Anaerobic Digesters

ANAGEN-Biogas® Advantages & Benefits

– Provides Essential Trace Elements for Methanogenic Bacteria

-Improves Methane Production

– Better Digestion, Less Disposal

– Prevents Digesters From Going Sour

– Restores Stability

– Stops Foaming

– Works Well For Food and Brewery Industries

The Science Behind It

Methanogens Require Trace Elements

Methane production is both important for biogas and digester health. When methanogens don’t receive adequate food, the result is an overabundance of acid in the digester and a sharp drop in methane production.

Trace elements like cobalt, nickel, and iron are essential components to the output of methanogenic bacteria. These bacteria need a steady supply of trace elements to form the biocatalysts necessary for methane production. Aquafix has developed a form of these crucial metals that is 100% bioavailable, which means the metals have been formulated to be completely absorbed by the bacterial cells. Putting in simple or commodity-based forms of these metals will not have any effect, as they are not taken up or used by the biology

Anaerobic Digester Upset & Troubleshooting

I. Recommended Operating Conditions

Temperature

- Mesophilic digesters temperatures should be maintained between 32-35°C

- Temperature changes per day should be no more than 2-3°C per day. A .5°C change per day is ideal.

Most anaerobic digesters are mesophilic. This is because mesophilic temperature conditions are easier to maintain than thermophilic. Mesophilic digesters require a consistent temperature between 32-35°C (90-95°F) as opposed to 50-60°C for thermophilic conditions (Gerardi 127). Falling outside this range of conditions can cause methane production to slow down which leads to a volatile acid buildup. Generally, the high end of the temperature range is preferable because it allows for faster biocatalyst function, sludge reduction, and methane production. An important consideration is to not allow any rapid change in temperature to occur. Mesophilic digesters should never change temperature to more than 2-3°C per day (Gerardi 91). In fact, some sources recommended only allowing a change of .5°C per day. It is important that if the temperature of a digester drops, its temperature is not recovered too quickly. This can very easily lead to an upset digester.

Thermophilic Digesters

Thermophilic digesters are typically operated between 50-60°. This higher operating temperature leads to a variety of advantages and disadvantages to the more commonly operated mesophilic digesters. The main reason thermophilic digesters are not more commonly used is due to the significantly higher energy input required to maintain a temperature above 50° C, but there are many other factors that could encourage or discourage the use of thermophilic digestion. The most important thing to know is that everything happens faster with thermophilic digesters, which includes upsets.

PROS

- Much faster COD reduction with consistent loading

- Improved solid/liquid separation

- Somewhat increased methane production

- Improved destruction of pathogens at high temperatures allows the production of class A bio-solids

- A higher rate of destruction of filamentous bacteria reduces the likelihood of filamentous foaming

- Faster decomposition of solids

CONS

- Much higher energy input

- Decreased bacterial diversity at higher temperatures leads to less digester stability

- Upsets occur much faster due to faster bacteria metabolism

- Poor degradation of long chain fatty acids at this temperature due to limited diversity of bacteria

- Poorer quality supernatant is produced

- Tends to generate more propionic acid which can cause problems with methane generation

- A less stable process requires more consistent organic loading to operate consistently

Because of these pros and cons, thermophilic digesters tend to be less suited for domestic wastewater treatment but can be very effective for COD reduction in consistent industrial waste. Thermophilic digesters require even more stable temperature and loading conditions than mesophilic digesters. Class A bio-solids production also could create a financial incentive that could compensate for high energy input. The increase in methane production can also reduce electrical costs of operating a thermophilic digester somewhat. In plants with inconsistent loading, benefits of thermophilic systems can be outweighed by an increased likelihood of upsets.

pH and Alkalinity:

- VA/Alk ratio should be below 0.34 (0.1 is better) to maintain a stable pH

- VA/Alk ratio can be calculated by dividing the total volatile acids in a solution by the total alkalinity

- Drops in pH reduce methane generation which causes digester souring

- pH should be between 6.8-7.2

- High pH is usually self-correcting but can cause Ammonia buildup

- pH adjustments should be made only after consulting Aquafix: 888-757-9577

Downloads

SELECT-pH®

SELECT-pH®

For pH Adjustment

Parklink’s new pH adjustment product, SELECT-pH®, will raise and stabilize the pH in aerobic and anaerobic processes, while minimizing sludge production. This can also help flocculation and dewatering in aerobic processes. SELECT-pH® is a blend of magnesium hydroxide, hydrated lime, sodium bicarbonate, sodium carbonate. The combination of these ingredients provides vastly superior pH stabilization when compared to either ingredient alone.

The Science Behind It

SELECT-pH® was developed from the continual supply of wastewater samples coming through our lab and customers asking for the easiest and safest means of stabilizing their pH. The combination of hydroxide, carbonate, and bicarbonate alkalinity, combined with beneficial cations calcium and magnesium makes this an ideal choice. Methods of raising the pH tend to be more straight forward, while stabilizing the pH is a larger challenge for most wastewater operators. This product will buffer water in a way the individual ingredients cannot. This unique blend is excellent at buffering the pH efficiently and safely and is great for modest pH adjustment.

SELECT-pH® is recommended when the pH is 6.0 or higher and the customer wants to get into a pH 7.0 to 8.0 range. When the pH is lower than 6.0 we recommend our high purity magnesium hydroxide product to get the pH up into the 6 range and then our SELECT-pH® to stabilize and hold the pH. In these low pH, magnesium hydroxide has a high solubility and as the pH goes higher the solubility decreases and it forms sludge. For this reason, SELECT-pH® only contains a small amount of magnesium hydroxide which allows us to get the benefits of the product without creating sludge at high pH.

Aerobic Wastewater Processes and Calcium/Magnesium Bridging to Improve Floc Formation

In addition to being effective at maintaining a balanced pH, SELECT-pH® contains high levels of calcium and magnesium which have demonstrated an ability to improve floc formation by improving calcium/magnesium bridging. Higher levels of the cations calcium and magnesium alter the surface charge of EPS (extracellular polymeric substances) in a way that provides more consistent floc formation. Typically, this means, the higher the ratio of calcium and magnesium to sodium and potassium, the better the floc formation.

Raising the pH in an Anaerobic Digester

Increasing the pH in an anaerobic digester can be difficult for several reasons:

Typically, inexpensive methods such as hydrated lime are insoluble which lead to excess sludge accumulation in a digester. Lime sludge interferes with mixing and reduces digester capacity which can lead to extra hauling and reduced methane generation.

Sodium hydroxide is soluble and can increase pH quickly, but is hazardous and has a risk of overshooting the pH. Baking soda, would be a good option due to high solubility and excellent buffering capacity, but tends to require high volumes to adjust the pH in a digester effectively and can lead to sodium toxicity.

For these reasons we recommend first adjusting the pH of the digester in question with our high purity magnesium hydroxide to pH 6-7, then using Boost N Lock to bring the pH in the 7’s to promote stability. SELECT-pH® can then be used as a low dose maintenance tool to maintain good alkalinity, preventing future digester upsets.

Simple Titration Method for Boost N Lock or other pH adjustment products

If you are unfamiliar with titrations, feel free to contact Aquafix with questions. Be careful when handling strong bases such as sodium hydroxide as they can cause severe chemical burns. SELECT-pH®, calcium hydroxide, magnesium hydroxide, sodium bicarbonate, sodium carbonate, and calcium oxide will not cause any problems other than minor skin irritation but ideally you should still not work with these compounds unless you are using a dust mask, and eye protection.

For safety, we recommend performing this test using a dust mask, safety goggles, and gloves. If compound used gets on your skin, wash with soap and water. If any of these compounds get in your eyes, we recommend immediately using an eye-wash to rinse eyes for at least 15 minutes.

1. Prepare Chemicals- Make a slurry mixture of 50 g of SELECT-pH® and 1000 mL of distilled water. Add the slurry to a bottle or container with cover so it can be shaken up regularly.

2. Prepare Sample to Be Tested- Collect 500 mL of well mixed (if possible) anaerobic digester sample in a 1000 mL beaker. Place the beaker on a mixing plate with a magnetic stirrer or put in a 1000 mL contain and shake to mix if necessary.

3. Add SELECT-pH® Until Desired pH Is Achieved- Test and record the initial pH, then add 5 mL portions of the Boost N Lock Slurry to the continuously mixed beaker of digester sample. After each 5 mL addition, mix the digester sample for 3 minutes and then test and record the pH and add another 5 mL until the pH is at 7. SELECT-pH® or any other slurry should be shaken or mixed before each 5 mL addition.

4. Calculate Dose Required for Full Scale Treatment- Once the pH reaches 7, the dose of 5 mL equates to 210# of SELECT-pH® (or mag/calcium hydroxide) per 100,000 gallons digester volume. This means you will need to add 210 pounds of SELECT-pH® per 100,000 gallons digester volume or other solid pH adjuster for each 5 mL added to the beaker.

Footnotes:

A. This procedure can also be used for magnesium, or calcium hydroxide. Generally, we recommend increasing the pH to 6 with an inexpensive base like magnesium hydroxide and use SELECT-pH® to finish the pH adjustment to improve pH stability.

B. Dose rate can be further refined by repeating the test but only adding 1 mL at a time of pH adjustment slurry/solution. This equates to 42 pounds per 100,000 gallons.

C. Procedure can be used for fully soluble compounds such as sodium carbonate or liquid pH adjusters. Different calculations may be needed for liquids.

Benefits

Excellent buffering capacity

Dramatically lower dose rates than either ingredient individually

Produces a minimum of excess sludge

Good at raising the pH when it is 6.0 or higher

Safe for the biology and the user

Lower in sodium than straight soda ash or sodium bicarbonate

Calcium and magnesium can aid in intra-floc bridging