Wastewater Treatment

Aeration and Oxygenation

Patented Double Bubble Technology™

The purpose of wastewater aeration is twofold:

1. To supply the required oxygen to the metabolizing microorganisms; and

2. To provide mixing so that the microorganisms come into contact with the dissolved and suspended organic matter.

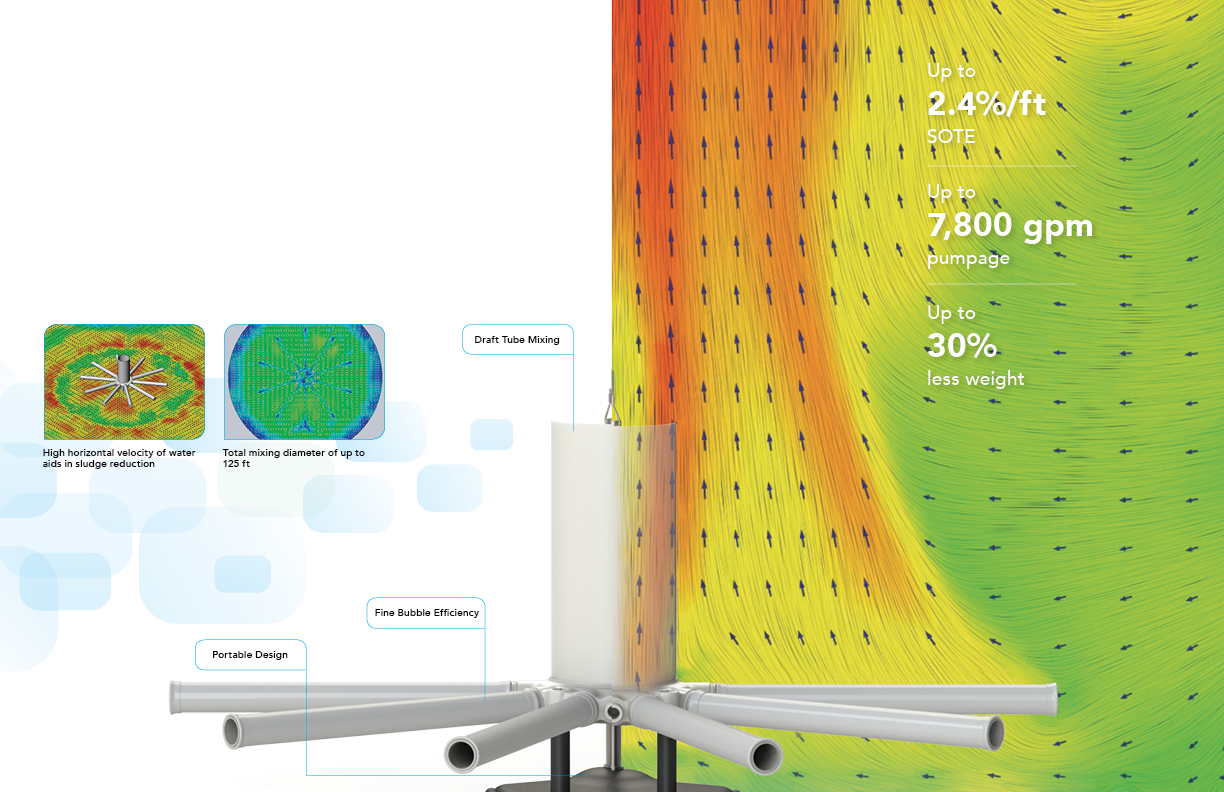

The Patented Double Bubble Technology™ utilized by the ARES Aerator is designed specifically to mix and aerate in one portable unit. The ARES utilizes fine bubble diffusers to efficiently supply oxygen while attaining a high level of aeration energy efficiency. A coarse bubble static tube creates the mixing. This allows the microorganisms to contact with the dissolved and suspended organic matter.

Efficient Mixing & Aeration in One Portable Unit

Ares Lagoon Aeration

Ares Lagoon Aeration

The Ares Lagoon Aerator cut its teeth in Municipal Wastewater Treatment over a decade ago. With both mixing and aeration incorporated into one portable aerator, the Ares can be successfully utilised in:

• Wastewater aeration lagoons

• Wastewater aeration tanks

• Flow equalization basins

• Reclaimed water storage reservoirs

• And much more.

Let us put our 30+ years of wastewater engineering experience to work for you!

Energy Efficiency and Cost

Extensive independent testing has proven that the Ares Aerator has a best-in-industry Standard Aeration Efficiency (SAE). The MARS is 50-60% more energy-efficient than high-speed surface aerators and 40-50% more efficient than coarse bubble diffusers.

Energy efficiency is further enhanced by the patented Double-Bubble Technology which allows custom optimisation of each system’s fine bubble (oxygenation) and coarse bubble mixing demands.

The Ares Aeration System includes a broad range of product models and options. Our engineering team designs systems that are customised to meet your facilities unique requirements while also targeting the fastest possible project payback period with significant energy savings. This payback period often falls within 12-36 months.

Benefits

1. Aeration, Mixing and Portability. – The Ares Lagoon Aeration System provides wastewater lagoon aeration and mixing in one portable aerator. Utilising both fine bubble aeration and coarse bubble technology, the Ares is able to achieve efficient aeration and thorough mixing of the water column.

2. Easy System Installation. – Ares Aerators are simple to install to any wastewater lagoon facility. Each self-weighted unit is connected to an on-shore air supply via flexible weighted tubing and lowered into the water.

3. Simple System Maintenance. – Maintenance of the Ares Aeration System is equally as simple and can be completed from the surface without incurring system downtime. This hassle-free modular design allows for the MARS to treat any size wastewater facility.

Double Bubble Technology

1. Coarse Bubble Mixing: Large bubbles are released at the bottom of the static tube creating a draft effect that pulls water and liquefied organic matter up from the basin floor. This produces wastewater mixing by highly agitating the water column, thoroughly churning and circulating the entire basin.

2. Fine Bubble Aeration: Fine bubble diffusers surround the static tube, maximising oxygen transfer efficiency (OTE) while minimising energy consumption. Enhanced by the mixing effect of the coarse bubble, this combination provides the ideal environment for biological treatment.

3. Optimised Energy Distribution: The Ares’ modular design allows for treatment to be evenly distributed throughout the entire wastewater lagoon, mixing and aerating from the basin floor to the surface.

Lower Maintenance Costs

1. Ease of Maintenance: Each Ares is a portable aerator that is self-weighted and equipped with a stainless steel tether and locator float. When necessary, individual units can be easily lifted to the surface for servicing without the expense of dewatering or the inconvenience of system downtime.

2. Centralised Air Supply: Air can be supplied to the entire Ares Wastewater Lagoon Aeration System by a single, centralised on-shore blower. If needed, additional blowers can be provided to meet sizing, layout or redundancy requirements. For further energy savings and control, Variable Frequency Drives (VFD) and Dissolved Oxygen (DO) meters can be incorporated.

3. Anti-Fouling Design: The MARS Aerator resists fouling, clogging and general ‘wear-and-tear’ in several ways:

A. Utilising self-checked fine & coarse bubble diffusers

B. Using self-cleaning EPDM fine bubble membranes

C. Elevating the diffusers above accumulated solids

D. Eliminating all submerged moving parts.

Videos

Download Brochure

Bubble Tubing Aeration

Bubble Tubing Aeration

Fine bubble diffusers such as our Bubble Tubing® produce many tiny air bubbles (less than 1 mm in diameter). Tiny bubbles rise steadily from the floor of a wastewater treatment basin or the bottom of waterways and canals, ponds, lakes or lagoons. These bubbles provide substantial and efficient mass transfer of oxygen into the water. This oxygen, combined with the food source, sewage or sediment, allows naturally occurring bacteria to produce enzymes. Enzymes help break down waste or sediment made of accumulated organic matter.

Fine Bubble Technology at work

The size of the bubble matters greatly for the application as we have noticed in our work. The fine bubbles (microbubbles) are critical for achieving precise results whether oxygenating a wastewater treatment plant, using aeration to biologically remove excess nutrients, or using aeration for fluid mixing. Air bubble curtains applications that rely more on mixing and moving water also benefit from billions upon billions of microbubbles produced by Bubble Tubing®. Not only do bubbles transfer oxygen and decontaminate water by oxidation, but they also move and mix, clarify, and de-stratify water. Thus the same technology has many diverse applications.

Bubble Tubing® optimises oxygen transfer and lifts water which aids in total circulation throughout the water column. As it functions without moving parts or electricity in the water, it increases performance efficiency while significantly reducing electrical and maintenance costs in comparison to other aeration systems. This tubing, made of highly resistant yet flexible PVC, is non-kinking and holds no memory when deployed.

Features of Bubble Tubing®

- Bubble Tubing® is flexible, it holds no memory and will not kink, is easy to install and is safe for the environment (does not contain lead).

- Made exclusively in Canada to our exact specifications, impressive 5-year warranty.

- High oxygen transfer rate. A full evaluation of the oxygen transfer capabilities by independent firm available.

- Applications range from farm ponds to the largest industrial projects.

- Suitable for fresh and saltwater applications, from shallow to deep waters.

- Inner pressure prevents clogging; tubing is low maintenance, anti-fouling.

- No moving parts or electricity in the water.

- Highly resistant PVC (chemicals, salinity, temperature).

- Weighted and non-weighted formats available.

- Tubing can be purchased with all the necessary hardware, ready to be installed.

Operations: How does Bubble Tubing® work?

Compressed air enters the tubing creating an inner pressure. It is released through the perforations thanks to the precision holes found along both sides of the entire length of tubing. The ensuing micro-bubbles are efficient in preventing clogging and fouling (typically found in porous diffusers), of the entire length of tubing. They form a bubble curtain of uniform and evenly dispersed fine bubbles.

No matter the scale of operations the same basic principle applies: A compressor’s heat hose is attached to the airline delivery hose which itself is connected to the Bubble Tubing® equipped with a check valve. The compressor pushes the air through both the feeder hose and the diffuser tubing that releases the air uniformly into the water.

We offer all the necessary products from start to finish, to fully set-up a reliable and efficient aeration system for you. We can size the compressor for the application, suggest tubing layout, suggest cost effective design modifications, and offer to troubleshoot. Our experience designing aeration and deicing systems with Bubble Tubing® is substantial, and our expertise is sought for many aeration projects.

Silt Barrier and turbidity curtains to contain sediments in suspension

Bubble curtains also meet the requirement for containing silt and turbidity for in-situ work where sediment containment barriers are mandatory. When operating in a stream, river or lake, marine construction and dredging companies are required to install a physical curtain called a floating turbidity barrier.lick on picture to enlarge

These obstacles do not allow free passage for boats and work equipment. Whereas a bubble curtain does both: it allows movement of boats and equipment over the barrier while retaining sediment and other suspended matter. In this case, a bubble curtain installed from the stream, river or lake bed will mitigate the migration of silt and other suspended sediments through the water column.

Our Bubble Tubing® has proven to be very useful as a silt barrier and turbidity curtain during these applications. Also, in this article, research is currently underway to validate the effectiveness of bubble curtains in altering stream dynamics. Water currents in the outer curves of riverbeds are slower allowing for sediment deposition and accumulation. Over time, a sand bank can be created, making shipping impossible without dredging under certain circumstances. By installing a bubble curtain in this outer curve, this creates a sufficient current to prevent sediment buildup.

These are a few of the applications for Bubble Curtains. We look forward to working closely with engineers, scientists and water managers to find bubble curtain applications to protect wildlife and the environment so projects can move forward in an environmentally responsible manner.

Who may need to create a bubble barrier?

Demand for bubble curtains is booming. Who are our customers:

- Port authorities

- Shipbuilding companies

- Acoustic reduction specialists

- Environmental firms

- Hotel chains

- Oil platform managers

- Companies specialising in dredging

- Marine construction companies

- Hydroelectric dam managers

- Companies specialising in fish barriers

- Naval bases

- Environmental engineering firms

- Cities to recover waste in canals and rivers

- Floating waste recovery companies

- Environmental groups and citizen associations

Videos

Downloads

SELECT-Liquid02®

SELECT-Liquid02®

Select-Liquid02® is a liquid source of oxygen that helps to eliminate the low DO (dissolved oxygen) conditions, odours, and septicity. These conditions can occur in collection systems as well as activated sludge plants and aeration basins. A lack of dissolved oxygen can lead to bulking filaments like Thiothrix/021N, h. hydrossis, Sphaerotilus natans/Type 1701, and other filaments with sulphur granules. Odours caused by low DO can occur in collection systems as well as in lagoons, especially during the warmest months.

Select-Liquid02® helps to adjust ORP, offsetting septicity, and promoting metabolic activity of aerobic bacteria.

The Science Behind It

Select-Liquid02® is an easy to apply liquid micronutrient that promotes metabolic activity of the aerobic bacteria. Simply inject OxyFresh into the basin when you need it most (during periods of overloading or hot weather). The plant will recover from low DO faster and have fewer odours with Select-Liquid02®. Blended into OxyFresh are odour neutralizers that knock out offensive odours.

Select-Liquid02® is often used in lift stations as well. Select-Liquid02®will prevent downstream odours.

Applications and Benefits

Select-Liquid02® Applications

– Wastewater Plants

– Aerobic Digestor

– Lift Station

– Hauling Tanks

Select-Liquid02® Benefits for O2 and Odor Control

– Prevents Downstream Odours

– Fewer Odours

– Fast Recovery

– Easy to Apply

Downloads

SELECT-Oxypack®

SELECT-Oxypack®

Oxygen Booster

SELECT-Oxypack® Lagoon Oxygen Booster is a granular oxygen source that is used in wastewater lagoons and ponds to accelerate the digestion of sludge and prevent odours.

SELECT-Oxypack® is a biostimulant and sludge digestion accelerator that really kicks the bacteria into overdrive to chew up sludge.

The Science Behind It

When added to a lagoon, SELECT-Oxypack® – Lagoon Oxygen Booster sinks down into the sludge layer. As the pack dissolves, peroxide liberates the sludge and punches holes in the muck layer. This increases the surface area and allows new pathways for the bacteria to get deeper into the sludge. The effect on the sludge layer is similar to core aerating your lawn. It also adds oxygen to the often anaerobic muck layer, to minimize odour production.

SELECT-Sediment® and SELECT-Oxypack® are also a good combination for wastewater operations with percolation ponds and rock filters.

Percolation ponds and rock filters tend to build up with sludge and dead organics. These clog the surface and prevent water from trickling through them. The use of both these products and help break up and digest organic matter so the water starts flowing again.

SELECT-Oxypack®– Oxygen Booster is sometimes used to offset toxicity, raise DO, and stimulate the bacterial environment in wastewater treatment plants. Call us if you have any questions, we’d be glad to help out.

Applications and Benefits

SELECT-Oxypack®Applications

– Wastewater Lagoons

– Decorative Ponds

– Sewer Lines

– Holding Tanks

– Lift Stations

– Wastewater Treatment Plants

SELECT-Oxypack® Benefits

– Promotes metabolic activity of the anaerobic bacteria

– Knocks out toxicity, sulphides and sulfide-based filaments

– Prevents downstream odours

– Neutralizes existing odours

– Easy to use